To serve you better, our new website displays information specific to your location.

Please visit the site and bookmark it for future use.

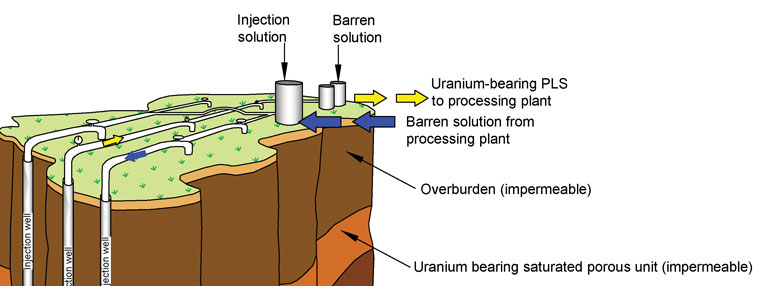

In-Situ Recovery

Where a uranium orebody exists in a saturated sandstone aquifer, boreholes can be drilled into it and the surrounding water treated with chemicals. This treatment enables the uranium to be dissolved and leached from the orebody, as the chemical solution circulates through it. The solution is then pumped back to the surface through different boreholes and the uranium is recovered. This process is known as solution mining. The aquifer is treated with either an acid or alkali, depending on the geological characteristics of the orebody.

In-Situ Recovery (ISR) is the preferred method for developing small uranium deposits contained in underground water systems (aquifers). This method is preferred because the deposit can be developed without destroying the aquifer, at a lower cost and with much less visual impact. The solution is brought to the surface processing plant, where it is treated with chemicals that cause the uranium to precipitate from the solution. The remaining solution is returned underground to its original source.

SRK has been involved in the evaluation, monitoring, design and development of several ISR projects located in the Czech Republic, Kazakhstan, Russia and the USA. Such projects require specialists in geological resource determination, geochemistry, process engineering and hydrogeology to collaborate in designing a wellfield to extract uranium, and then develop an appropriate recovery process plant to separate uranium from the leaching solutions. Such projects are attractive because they minimize surface disturbance and require considerably less capital investment than more conventional mining operations.

Currently, a team of consultants managed by Mr Jeff Volk, principal geologist in SRK Denver, from SRK offices in Cardiff, Denver and Moscow are collaborating on the evaluation and design of ISR projects at Khiagda in Russia and Zarechnoye in Kazakhstan. Members include SRK principal geochemist Dr Rob Bowell, senior geochemist Mr Kent Petersen, principal hydrogeologists Dr Vladimir Ugorets and Mr Larry Cope, and SRK senior process engineers Dr Matt Dey and Mr Dmitry Yermakov. These projects each aim to produce close to 1000 tonnes of uranium a year using ISR methods.

Rob Bowell: rbowell@srk.co.um

Dmitry Yermakov: dyermakov@srk.ru.com

|

You can download a PDF of the entire |

PDF A4

|

PDF Letter

|

|

|

|

Our newsletters focus on specific areas of interest to earth resource professionals and clients. Each is available as an Adobe Acrobat PDF file. If you don't already have Adobe's PDF reader, you can download it free.