To serve you better, our new website displays information specific to your location.

Please visit the site and bookmark it for future use.

You are here

SRK Kazakhstan ›Mechanisation in Indian underground coal mines: rock bolting technology and strata monitoring

SRK News | Issue 54: Rock Engineering and Slope Stability

Mechanised mining, using Continuous Miner (CM) bord and pillar sections, has been successfully introduced into Indian coal mines for more than a decade. This milestone was possible only with the concurrent introduction of advanced technology with rock bolting to provide reliable safe support. The application of this high capacity rock bolting system in India, including design based on in-situ measurement, together with systems for monitoring ground control safety, made mechanised mining successful. The success of these installations confirmed the large potential for further mechanised bord and pillar operations.

The innovative approach in rock mechanics leading to this rapid progress includes:

-

An improved understanding of underground stress fields and rock failure mechanisms

-

The adoption of high capacity bolting systems, based on this understanding

- The application of new geotechnical instruments for design optimisation and for monitoring ground control safety

The introduction of high capacity roof bolting systems, pillar extraction design and monitoring, with the new mining system, allowed both safe re-access to existing bord and pillar panels and the development of new panels. For high productivity, large dimension roadways were needed to transport high capacity equipment that requires a reliable support system. The rockbolt system introduced with mechanised mining was typically a high-strength full column, resinencapsulated bolt system, with twospeed resins and a torque tension system to facilitate good quality installation, plus dome plates to indicate overloading.

For overall improvement it was essential to follow proper installation procedures in addition to selecting appropriate roof bolting material and supplies. Training sessions, detailing basics and critical aspects on roof bolting procedures, were held to enhance the skill and awareness of operators and supervisors. The advancing technology of mechanised mining brings on challenges and the need to understand the behaviour of strata around the workings.

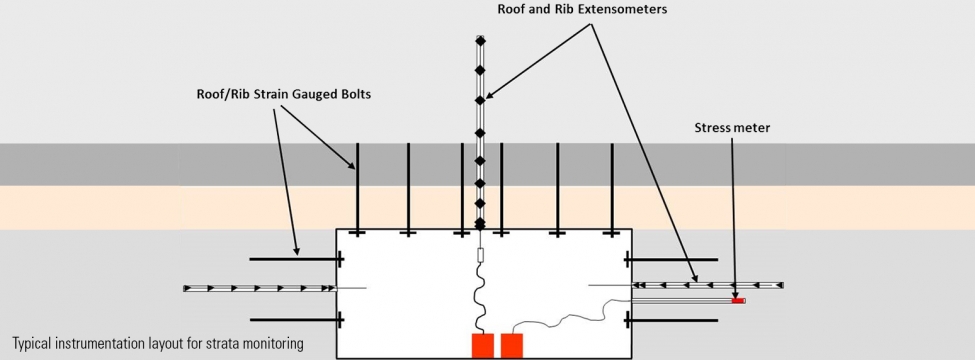

This emphasised the need to introduce a proper strata monitoring scheme for keeping more detailed records of the strata movement connected with faster extraction. A detailed series of instruments consists of various remotetype sensors for roof and ribs; stress meters for monitoring change in stress over the pillars; and for monitoring roof deformation through reported experiences and instructions.

Various trials in India showed that systematic study, and the design of supports, followed by proper implementation in the field, makes a significant contribution to the productivity and meticulous monitoring that provides safety for operators during pillar extraction.

Atul Gandhe: agandhe@srk.co.in