To serve you better, our new website displays information specific to your location.

Please visit the site and bookmark it for future use.

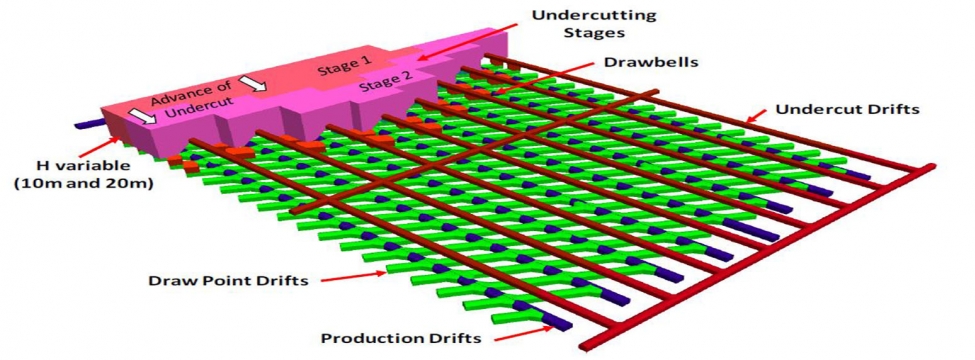

Influence of the undercut height on the behaviour of pillars at the extraction level in block and panel caving operations

Definition of the undercutting geometry and size is an essential aspect of the design of a block and panel caving operation. Both geometry and size need to be properly established to guarantee the initiation and the development of sustainable propagation of the caving process in a rock mass. Although the required extent of the undercut in the horizontal directions needed for caving management and to avoid damage to pillars has been studied in some detail, the required height of the flat undercut has not received similar attention. Few existing studies suggest that the smaller the height of the undercut, the higher the stress concentrations and, therefore, the higher the magnitude of stresses at the front or abutment of the undercut. These stress concentrations, in turn, can produce negative effects, such as damage in pillars and drifts at both the undercut level (UCL) and extraction level (EXL). This paper investigates the effect of the undercut height on the mechanical response of the rock mass and mine openings in a block caving operation. With this purpose, the problem is simulated using a three-dimensional mechanical model that considers undercut heights of 5, 10, 20 and 40 m in a typical block/panel caving operation. The model comprises the extraction level, the undercutting level and the broken material surfaces that simulate the undercutting advance. Simulation of the mining process allows one to see the effect that the assumed heights of undercut have on the stress concentrations and plastic damage in pillars at the vicinity of the caving front. Results of the numerical models are correlated with observations of pillar damage in caving layouts used at some mines in Chile.