To serve you better, our new website displays information specific to your location.

Please visit the site and bookmark it for future use.

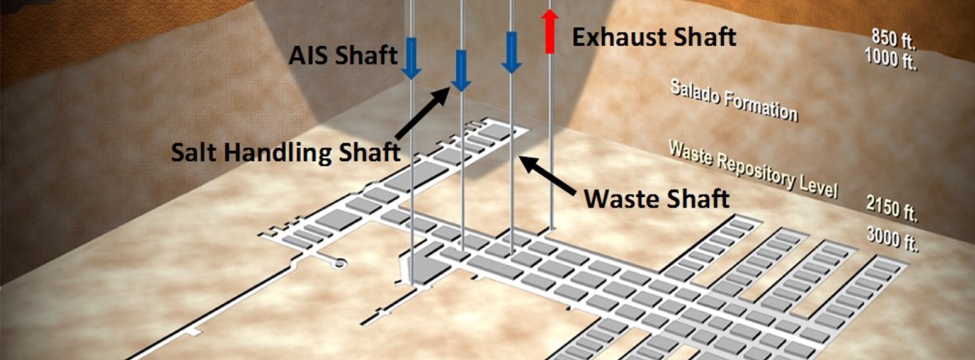

Underground Ventilation System Analysis at WIPP

Author(s):

Nathan Wineinger, Keith Wallace

Date:

Monday, June 19, 2017

First presented:

16th North America Mine Ventilation Symposium

Media:

Type:

Presentation

Category:

Mine Ventilation

On the evening of February 14, 2014, radiological sensors underground at the Department of Energy’s (DOE) Waste Isolation Pilot Plant (WIPP) facility detected a radiation release. This sensor triggered a reconfiguration of the ventilation system from a flow of 123 m3/s (260,000 cfm) to 28.3 m3/s (60,000 cfm) through two HEPA filtration trains. The ventilation system has been kept at a filtered flow of 28.3 m3/s (60,000 cfm) since the radiation event. The DOE is currently investigating upgrades to the ventilation system that will include additional surface fans and filtration units, an additional booster fan in the underground, and a long range recovery ventilation plan. SRK with NWP engineers extensively modeled the underground ventilation system at WIPP to determine if a single differential pressure sensor at one strategic location could be used to validate the underground airflow distribution. A proper alignment for the underground ventilation system is airflow passing from the “clean” side to the disposal side with all disposal air exhausting through surface fans with filtration units. This paper describes this study and its conclusion that it was possible to use a single device to monitor for ventilation configuration acceptance with multiple upset conditions.