To serve you better, our new website displays information specific to your location.

Please visit the site and bookmark it for future use.

You are here

SRK Kazakhstan ›A dynamic approach to drill programme design

SRK News | Issue 57: Exploration Geology: Keys to succes

Harri Rees, Exploration Geologist

Dan Marsh, Exploration Geologist

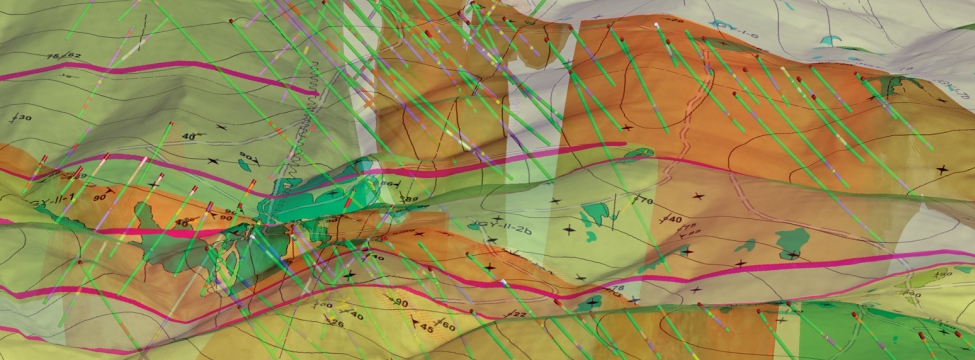

With clients’ exploration budgets being squeezed, long gone are the days of planning collar locations and orientations for a whole drilling programme at the outset of a campaign. It is now imperative that the modern exploration geologist can plan holes on the fly, modify drilling locations to achieve successful drilling intercepts, and maximise time and budgets. Although it has detractors, the introduction of implicit modelling software programs has revolutionised geological modelling. This allows geologists to visualise data effectively, identify crucial trends and structures, and rapidly create multiple interpretations of geological and mineralisation models, compared to CAD-based methods of 10 years ago. SRK has embraced implicit modelling software, like Leapfrog Geo, and uses them as a valuable tool in dynamic exploration programme design.

SRK recently used Leapfrog Geo this way to great effect during a long-term drilling programme for a client in Saudi Arabia. SRK was brought in to design and supervise a surface mapping and diamond drilling programme which hosts discrete, discontinuous, gold-bearing quartz veins. The data collected and interpretations made were then used to build the Mineral Resource Estimation completed by SRK.

SRK recognised this opportunity to create a dynamic programme design with implicit modelling. Data collected in the field could immediately be used to update a working 3D geological model, then used to direct drill-targeting in real-time. Informed decisions regarding collar positioning, borehole density, drilling orientations, and end of hole could be made swiftly based on evolving data. The dynamic quality control of drilling data meant assessing issues and bias as they arise. In this approach the targets were drilled and the drilling budgets optimised.

With the gradual addition of mapping and logging data, a dynamic but more holistic model could be produced. Also, regular programme updates could be distributed through 3D visualisations.

While the usefulness of implicit modelling has been well established, quality technical, geological, and structural data must be collected and interpreted in a traditional manner. Drafting scaled cross sections showing drillhole fences with annotated interpretations should continue in drill programme management. This ensures that the geologist understands and interprets the geology rather than rely on a “black-box” approach using software. The project geologists can then scan these cross sections and reference them within the software to assist with 3D digital interpretation.

Harri Rees: hrees@srkexploration.com