To serve you better, our new website displays information specific to your location.

Please visit the site and bookmark it for future use.

Integration of Field Erosion Measurements with Erosion Models and 3D Design Tools for Development of Erosion Resistant Cover Systems

Author(s):

Rahul Peroor

Date:

Thursday, September 5, 2019

First presented:

ACG Mine Closure 2019

Media:

Type:

Presentation

Category:

Environmental/Social

Post-closure maintenance activities for various inactive copper tailings impoundments owned by BHP in Arizona (USA) require frequent erosion-related inspections and repairs. BHP assessed these recurring costs and post-closure hazards and commissioned a study of alternative methods to design a more robust, erosion-resistant solution. The study combined field erosion testing, 2D and 3D erosion models, and landform design tools in an innovative way that allowed BHP to make an informed decision regarding improvements to the erosional stability of the tailings impoundments.

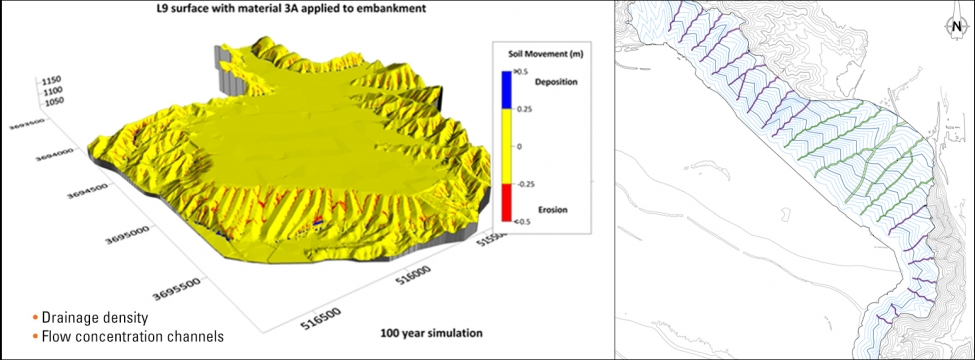

The study started with field-based material testing. Simulated rainfall and overland flows were applied to 13 test surfaces representing different cover systems, and measurements of infiltration capacity, interrill and rill erodibility, flow shear stress, and sediment size and density distributions were made. The field measurements allowed calibration of parameters for the Water Erosion Prediction Project (WEPP) erosion model and SIBERIA landform evolution model for the different cover systems. The study team used the calibrated WEPP model to evaluate the erosion performance of linear and curvilinear embankment profiles and retained cover systems that met minimum erosion performance standards. The performance standards were established using data on the erosion of surrounding undisturbed vegetated hillslopes and a review of the published literature detailing erosion benchmarks for rangelands in southwestern USA.

The design team developed 3D surfaces of the linear and curvilinear slope profiles developed from WEPP modelling, and more complex 3D surfaces developed from the GeoFluvTM software. These surfaces were subjected to 3D landform evolution modelling using SIBERIA. Inputs to the SIBERIA model and GeoFluvTM software were informed using data collected during the field studies. Each SIBERIA model iteration provided insight regarding short-term and long-term erosion performance for each 3D surface and cover system. The design team produced initial and sustaining capital cost estimates for the final engineering designs based on this output.

This presentation details the innovative approach taken to integrate field measures of erodibility, 2D and 3D models, and civil 3D design software to produce defensible long-term closure designs that are material and site specific, and cost-effective.